Real matcha comes from Japan and it is a fine powder made from green tea leaves. Growing quality matcha has a lot to do with the terroir, or the natural environment in which it is produced, including the soil, topography, and climate.

The full cultivation and production process is very sophisticated. The Japanese have been producing quality matcha for more than 800 years, with the skills for doing so passed down from generation to generation, however, very few tea farmers know how to produce matcha. In fact, of Japan’s 30,000 tea farmers, there are only 500 who produce matcha!

Step 1 Shade-grown tea plants

Like all tea, Matcha is made from the tea plant Camellia sinensis, it is the way that it is cultivated and then processed that makes it so special.

Tea leaves grown for Matcha are shaded with bamboo three to four weeks before harvesting. This process boosts the nutrient levels of matcha to extraordinary levels, with the leaves becoming packed with chlorophyll and amino acids.

The plants, which grow in near darkness, compensate for the lack of light by producing an intense amount of chlorophyll. The overproduction of chlorophyll also contributes to the distinctive bright green colour of quality matcha.

Shading the plants also yields an increase in the development of the amino acid L theanine, which gives you that Zen feeling you get when drinking quality matcha and which is also thought to give it its umami flavour.

Step 2 Harvesting and Processing the Leaves

When the plants are ready for harvest, the leaves are hand-picked from the top third of the plant where the highest concentration of nutrients is found. They are then steamed, dried, destemmed, and deveined. Steaming the leaves stops the oxidation process thus preserving the nutrients and colour.De-stemming and deveining the leaves is essential for ensuring a smooth texture and fine taste.

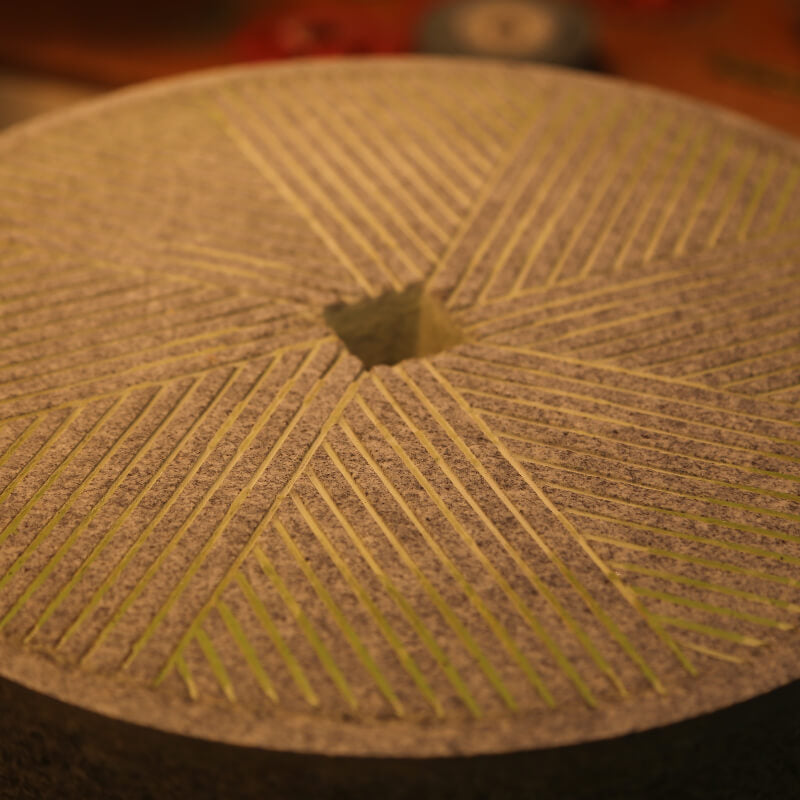

The pure leaves, known as “tencha” at this stage, are then expertly ground into a fine powder, using a granite stone mill. It takes an hour for a traditional granite stone mill to grind 30 to 40 grams of matcha – the amount in one tin. Faster grinding would burn and spoil the leaves.

Granite stone mills are the traditional method for grinding tencha leaves and quality matcha, like OMGTea, is still ground using them. It is this process that that gives it a super fine texture, a similar consistency to baby powder.

Unfortunately, however, there are many Matcha products on the market now that are either pulverized by steel balls, or by high-powered blenders, which can completely destroy the integrity, quality, bio-availability (destroying the nutrients) and flavour of your Matcha tea. Mass producing Matcha in this fashion can also produce larger particle sizes (not the fine micron that traditional stone mills produce), which doesn't make for as smooth or flavourful of a cup.

Step 3 Packing in sealed tins

Following the grinding process, our matcha is packed into tins straight away and mechanically sealed airtight to ensure maximum freshness from Japan all the way to your home!